|

Steel Column |

|

|

|

|

|

|

|

Steel Column |

|

|

|

|

|

Steel Column

This program can analyze or design a standard AISC steel section subjected to axial loads and simultaneous bending moments about each axis. A variety of factors can be specified which effect the AISC code stress analysis of the beam. Unbraced compression flange lengths, minor axis bending, primary or secondary member status, and load duration factors can all be modified for the beam you are analyzing or designing.

Fixed and pinned supports can be used at either end, allowing analysis for the following types: Fix/Fix, Pin/Pin, Fix/Pin, Pin/Fix, or Fix/Free.

Axial dead, live, and short term loads may be applied to the column at eccentricities for both axes. Also, concentrated moments, point loads, and distributed loads can be applied to the column as beam-type loads, causing moments about the X-X and Y-Y axis from dead, live, and short term components .

To help you specify AISC sections to be analyzed, an internal database system gives you access to over 4,000 sections from the 6th, 7th, 8th, and 9th edition AISC handbooks. Data for these sections was acquired from many published sources, and represents the only standard rolled sections economically available to constructors in the United States.

You can either type in a section and have it's properties automatically recalled, or display a window to scroll through the database of sections. Sections available include W, H, S, M, C, MC, B, JR, TS, P, WT, ST, MT, L, and LL.

A comprehensive analysis procedure provides moments and maximum and allowable axial and bending stresses. A very thorough AISC code check procedure determines allowable bending stresses for all members, considering compact section criteria and lateral buckling due to slenderness effects.

Basic Usage

| • | From the actual span condition of the column, enter the total column height to be used for slenderness and moment calculations. By entering 1, 2, 3, 4, or 5 you can easily specify a variety of support conditions. However, this fixity is assumed about BOTH AXES. At one end of the column, you can't have Y-Y bending fixed while allowing X-X axis rotation. You will also need to specify the unbraced lengths to be used for calculating bending and axial stresses. |

| • | When you are using condition 5", Fix/Free, the bottom of the column is considered fixed. |

| • | The X-X axis is always considered the major axis. Entering Y-Y axis loads, moments, and axial eccentricity will generate minor axis bending. |

| • | Sidesway indicates whether the column is free to deflect in the direction of the Y-Y or X-X axis. Sidesway effects the internal calculation of Cm. Effective length factors will be applied to the unbraced lengths to determine actual lengths for determining allowable axial stress (but not for determining allowable bending stress). |

| • | This program provides plenty of load capability for loading any part of the column. Axial dead, live, and short term loads can be applied with an eccentricity on each axis, resulting in concentrated moments being applied to the top of the column along with the axial load. Those moments will be combined with the applied loads about each axis to determine total combined stresses. The tabular load entry area allows you to specify point loads, moments, and uniform loads to the column, with each having dead, live, and short term components. All Dist. values position the load with respect to the Bottom of the column. |

| • | Section Properties can be entered by using the built-in section property databases. Please see the following two sections on using this capability. |

| • | Reviewing Forces and Stresses. In the Summary section of the worksheet, the results of AISC stress combination equations H1-1, H1-2, and H1-3 will be listed. Also, actual and allowable axial and bending stresses are given. |

Unique Features

As mentioned earlier, the user can either have a column automatically selected using your design criteria, or specify a section to be analyzed.

You can specify bending loads on the column in addition to the axial loads, and all loads can have dead, live, and short term components.

Any W, H, S, M, B, JR, C, MC, TS, P, WT, ST, MT, L, or LL sections listed in the databases will have a thorough AISC code working stress analysis performed, including checks for lateral buckling and compactness for all provisions including appendix C.

Assumptions & Limitations

The unbraced lengths used for axial stress slenderness and lateral torsional buckling calculations are considered to be the same.

Steel Section Database

Built into the software is a complete database of common rolled sections available from various mills in the United States. On each tab labeled #1, #2, etc. there will be a button that looks like this:

![]()

This button displays the steel section database as shown below.

On this window there are various controls and options.....

Steel Database : Allows you to select between several common shapes databases.

Section Type to Display: Allows you to select which steel section designation to display in the list. These shapes conform to the American Institute of Steel Construction shape designations. To make your selection simply move the mouse over the letter(s) and when the highlight activates left-click once with your left mouse button.

Depth Range: This item allows you to specify depth limits to be used for selecting which sections to display in the list. When the checkbox to the left is not checked the selection wording and entries will not appear and all sections will be displayed. These dimensions are compared to the "Depth" dimension of the sections.

Class Range : This item allows you to specify the limits in "Depth Class" to be displayed in the table. The "Depth Class" of a section is the first numeric number in the sections name. For instance a wide flange W14x22 is in depth class "14". a channel C9x15 is in depth class "9", and a L5x3x1/4 is in depth class "5".

Equal & Unequal Legs : These two buttons appear when you have selected section type "L" which are single angles. The limit the display of the list to angle with equal dimension or unequal dimension sides.

Equal Legs, Long Leg Vertical, Short Leg Vertical: These three buttons appear when you have chosen to display section type "LL". These control the display of sections between pairs of angles with both sides of equal length, of unequal side length angles paired with the LONG side together, and unequal side length angles paired with the SHORTside together.

Square & Rectangular Tubes: These two buttons appear when you have chosen section types TS or HSS-T. These are square tubular sections. You can choose to display only square tubes or alternately tubes with unequal sides.

Sort Tabs for Database Table : Immediate above the database list of sections you will see tabs looking like this....

When selected each tab will sort the list in the order described by the text on that tab.

Sort order : These two buttons allow you to chose the list order of the sections. The sorting order will be according to the sort tab selected and shall be in ascending or descending order.

Database Table Itself : The main area on the window will be where the steel sections are displayed as a result of all of your choices as described above.

[Select] : This button is displayed when you have clicked on the [Section] button when you press [Select] the section in the list that is currently highlighted will be selected and the name and data brought into your calculation.

[Insert]: Use this button to add a steel section to the database. When pressed you will see the following window:

The only really important item to enter is the "Type" item. This specifies what standard rolled section type your section is. This item is used internally by the program to decide which stress analysis method to use for determining the sections allowable stress, how to consider unstiffenned elements, and many other code checking items.

[Change]: Will display the same window as above but allow you to change section properties.

[Delete] : Will enable you to delete sections. Note: No sections in the supplied database can be deleted. Only Sections that you ad can be later deleted.

[Cancel]: Exit the steel database window.

ASD & LRFD Design Modes

Allowable Stress Design and Load & Resistance Factor Design as specified by the American Institute of Steel Construction is provided by this program. Only screen captures and descriptions for ASD are presented in this book. More detailed LRFD documentation will be added and will be available in the electronically delivered versions of this book. Check these locations for electronic media:

| • | Latest Adobe Acrobat PDF documentation file here: ftp://208.36.30.226/sel5.pdf. |

| • | Latest Windows Help system file here : ftp://208.36.30.226/enercalc.hlp. |

| • | Internet HTML help documentation presented as web pages at www.enercalc.com/sel_help. |

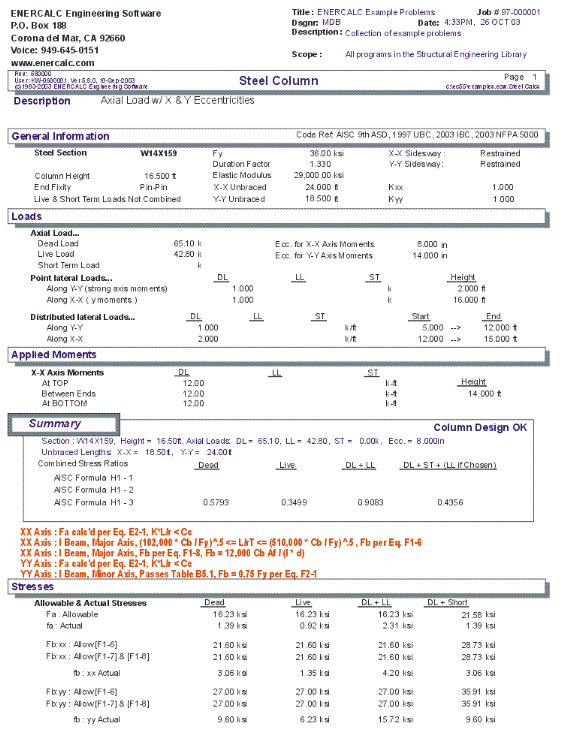

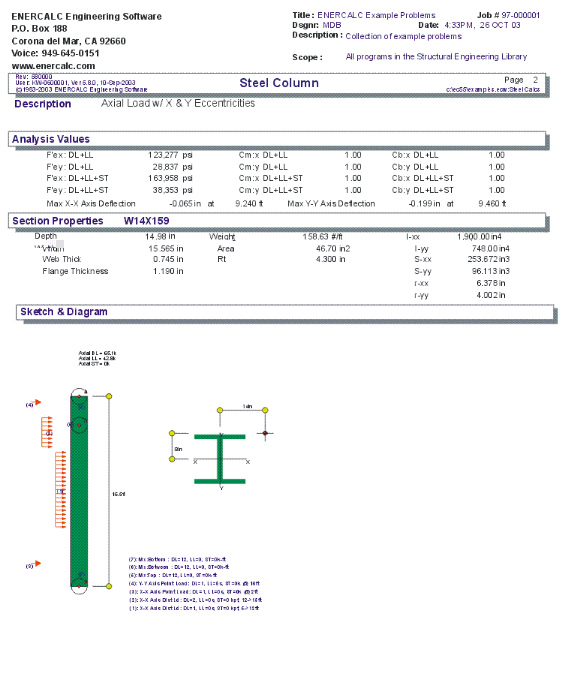

Example

The data entry for this example is shown in the screen captures that accompany the Data Entry Tabs and Results & Graphics Tabs sections to follow.

Data Entry Tabs

This set of tabs provides entries for all input in this calculation. While you are entering data and switching between these tabs you can view the desired resulting information on the tabs on the right-hand side of the screen (calculated values, sketches, diagrams, etc.). A recalculation is performed after any entry data is changed. After each data entry you can view the results on the right-hand set of tabs.

General Tab

This tab provides the data entry for all items in the calculation except loadings.

Column Height

The total column height is used to calculate moments applied to the column as Applied Loads.

Distance between bracing preventing deflection along Axis

This is the actual unbraced length of the column with respect to the X-X and Y-Y axis. This unbraced length will be multiplied by the effective length factor to determine the overall slenderness of the column about each axis.

The "X-X Unbraced" length entry specifies the distance between elements that are bracing the column against movement along it's local X-X axis. For wide flange beams this is parallel to the flanges. Similar definition holds for bracing lengths for the Y-Y axis movement.

Sidesway Status

Indicate whether or not the column is subject to sidesway. Enter a 1" if sidesway will be restrained, 0" if it will not. Sidesway is used for determining CM.

Kxx & Kyy Values

This effective length factor should be evaluated by the user according to the actual conditions present or anticipated. Reference is made to Table C1.8.1 and Figure C1.8.2 of the 1989 AISC specification and other sources on structural stability. These factors will modify the Unbraced Length value to determine the actual unbraced length to be used in the analysis.

End Fixities

The steel column can have any of five different end fixity combinations; Fix/Fix, Pin/Pin, Fix/Pin, Pin/Fix, or Fix/Free. These refer to the bottom and top column ends respectively. However, the end fixities apply to BOTH X-X and Y-Y axes.

If you are designing a column with end moments calculated from another program (e.g. FastFrame), set the support fixity to Pin/Pin and enter the end moments as Top and Bottom moments. DO NOT USE FIXED/FIXED support condition.

For all the end fixity combinations, remember the order is Bottom/Top. For example, Fix/Pin = Fixed @ Bottom and Pinned @ Top.

Steel Section

This is where you specify the rolled steel section to be used in the design. There are two ways to enter & specify the section.

| • | Use the [Section] button to retrieve the section from the built-in steel database. See the description given previously for more information. |

| • | Type in the section name and the program will automatically look through the database for a match. Upper or lower case is fine. If found the name and numeric section properties will be retrieved into this calculation. The numeric properties will be seen on the "Section Properties" tab. |

Fy

Yield Strength Indicates the yield strength of the steel section.

Include Live Load w/ Short Term Loads ?

Typically when short-term loads are from seismic events, the live load is not used. This YES/NO entry specifies whether your live loads will be used with short-term loads.

Load Duration Factor

Load duration factor is applied to the calculated allowable stresses and displayed as Allowable Stress in the Summary section.

Elastic Modulus

Although rarely does this need to be changed, enter the elastic modulus of the steel material.

Point & Distributed Loads Tab

Axial Loads

Specify your the axial loads acting on the column. Positive values apply compression to the column.

Axial Eccentricity

Enter the eccentricity from the geometric center of the column to the location where the axial load is applied if you want to consider the effect of axial load induced moments in your design.

Point Lateral Loads

Using these entries you can apply lateral loads between the endpoints of the column. Loads applied "Along Y-Y" are applied parallel to the Y-Y axis of the steel section. For a wide flange section this is parallel to the web.

The "Height" location of the application of the point load is measured with respect to the bottom of the column. Note! Be careful if you are using "Fixed" column ends NOT to apply point loads at a 0.0 or Column Height location.....they will not act on the column and simply be taken by the end rigid supports.

Distributed Lateral Loads

Using these entries you can apply uniform lateral loads between the endpoints of the column. Loads applied "Along Y-Y" are applied parallel to the Y-Y axis of the steel section. For a wide flange section this is parallel to the web.

The "Start" and "End" Locations are entered as the distances from the column base,

Moments Tab

These entries allow you to specify applied moments at the top, bottom, or between the ends of the column. When entering a moment between the ends enter the "Distance above base" as the distance above what you are considering the bottom of the column. The important thing is that the distances you enter for all applied loads uses the same end of the column as the reference.

Note: Do not apply a moment to a "fixed" end of the column. You are just applying the load to a rigid end and none of the moment will create bending in the column.

Section Properties Tab

This secondary tab is where the steel section properties are listed. The properties shown here are used for the calculation.

The typical steel section measurements are given for the section chosen. When certain sections are used, the measurements will not conform to the typical W section naming conventions used here:

| • | For Tubes , Flange Thickness and Wall Thickness will both be set equal to the tube's wall thickness. rT is not used. |

| • | For Pipe , Flange Thickness and Wall Thickness both equal the pipe's wall thickness. Flange Width and Depth will both be set to the pipe's outside diameter. rT is not used. |

| • | For Channels , rT equals the distance from the flat face to the center of gravity of the section. |

| • | For Tees , rT equals the distance from the top of the flange to the center of gravity of the section. |

| • | For Double Angles, rT equals the spacing between the backs of the angles. |

| • | For Single Angles, rT is not used. |

Results & Graphics Tabs

This set of tabs provides the calculated values resulting from your input on the "Data Entry Tabs". Because a recalculation is performed with each data entry, the information on these tabs always reflects the accurate and current results, problem sketch, or stress/deflection diagram.

Summary Tab

The summary area provides results of combining all generated moments about both axes with axial load stresses. The three AISC interaction equations indicate the state of combined stresses within the column.

| • | Formula H1-1 The result of applying the values calculated in the following section to AISC interaction formula H1-1. |

| • | Formula H1-2 The result of applying the values calculated in the following section to AISC interaction formula H1-2. |

| • | Formula H1-3 This is the result of applying the values calculated in the following section to AISC interaction formula H1-13, and is only used for column selection if fa/Fy 0.15. When fa/Fa exceeds 0.15, this value will be displayed as N/A. |

Axial & Bending Stresses

This table presents the results for different combinations of loadings on the column and their resulting calculated actual and allowable stresses.

Stress Check Comments

In this section, various messages will be displayed indicating what factors governed the calculation of allowable bending stress. The internal AISC code checking system can evaluate allowable stresses for all members EXCEPT SINGLE AND DOUBLE ANGLES. Although the program will calculate actual bending stresses, THE DESIGNER MUST DETERMINE IF THE BENDING IS VALID DUE TO THE UNEQUAL CROSS PRODUCT NATURE OF THE SECTION.

Details Tab

This tab present more details of the intermediate values calculated for the analysis of the allowable axial and bending stresses for the column.

Also given is the lateral deflections of the column for each axis as a result of applied lateral loads and a moment applied from an eccentric axial load.

Sketch Tab

This tab provides a sketch of the beam with loads and resulting values shown. Using the [Print Sketch] button will print the sketch in large scale on a single sheet of paper.

Printing Tab

This tab allows you to control which areas of the calculation to print. Checking a box will signal that the information described by the item will be printed. However, if there is no information in for a particular selection it will not be printed. So these checkboxes are best described as "If this particular area of the calculations contains data then print it".

Sample Printout